Crusher Equipment

- Sand Making Machine

- Stone Making Machine

- Stone Crusher

- Jaw Crusher

- Impact Crusher

- Cone Crusher

- Single-stage Hammer Crusher

- Ring Hammer Crusher

- Hammer Crusher

- Vertical Shaft Impact Crusher

- Fine Crusher

- Mobile Crusher Station

- Vibrating Feeder

- Vibrating Screen

- Belt Conveyor

- Sand Washing Machine

Beneficiation Equipment

- Beneficiation Equipment

- Ball Mill

- Ceramic Ball Mill

- Drier

- Metallurgy Rotary Kiln

- Magnetic Separator

- Classifier

- Flotation Machine

Construction Material

Home > Products

Autoclave Aerated Concrete Equipment

(1).Development and characteristics:Aerated concrete as an important part in the innovation of wall material and construction energy-saving is a kind of ideal material after application of years and can instead of clay brick. It has competence among wall materials. The government has clearly pointed that “Develop the aerated concrete blocks and the aerated concrete production line with annual capacity between 20,000 to 300,000 cubic meter; Autoclave maintenance and machinery cutting.” Because of the wall innovation and the advantages of the aerated concrete products, aerated concrete will be the most developed new construction materials in the recent 10 years with its light weight.

Aerated concrete has the advantages of light weight, good heat preservation and sound absorbing and is of certain intensity and can be processed, etc.

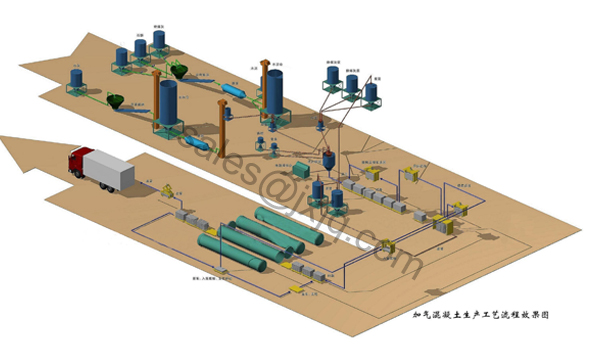

(2).Production Process of Aerate Concrete:

The equipment of aerate concrete can adopt favorable production process according to the type and feature. Under certain circumstance, grind the fly ash or silica sand or slag to be slurry by adding water. Then add powder lime, proper cement, plaster and vesicant and foam stabilizer. After stir, pour the slurry to the mold. When the slurry becomes solid, it can be cut into various sizes to be block or panel. Then put the blocks or panels into the autoclave by the hardening car. After the hardening of high temperature steam, concrete with light weight is made out.

(3). Equipments of Aerated Concrete Production

The model and quantity of the equipments of aerated concrete production is decided by the process design. Because of the process difference of the aerated concrete production, there is different equipment technology correspondingly to the production process. All those features are reflected on the cutting machine. It is related to the adjustment of the pouring style, mold, design of hardening car, cake transportation, remold, cutting, piling and the autoclave-entering style.

Shanghai Minggong Heavy Equipment Co.,Ltd. All rights reserved @ be by 2010.Record number: Shanghai 10023097 prepared. ICPZ

Address: No.299 Shenzhou Road,Fengxian District,Shanghai,China P.C.: 201499 E-mail: sales@jxjq.com

Address: No.299 Shenzhou Road,Fengxian District,Shanghai,China P.C.: 201499 E-mail: sales@jxjq.com